[UPDATE TO THIS STORY: Since this story was published in 2013, Lori Robinson has switched from growing potatoes to grains on her farm and, as such, is no longer growing potatoes. The story, however, remains a good depiction of what goes in to getting potato seed in the ground and how the potato ends up on your dinner table.]

Part of my objective with this food blog is to showcase food products produced on PEI and the producers and farmers behind them. In this story, I will introduce you to Lori Robinson, a fifth generation PEI potato farmer. Lori is Farm Manager at Eric C. Robinson Inc. in Albany, PEI.

I hope that this feature story will shed a little light on just where the bags of potatoes that you pick up at the supermarket come from or where the potatoes that go into making potato chips originate.

For the land mass size of our Province, PEI produces a lot of potatoes. According to the Prince Edward Island Potato Board, there were 89,000 acres of potatoes grown on PEI in 2013. The Board tells me there were approximately 45 varieties grown in commercial quantities and more than double that amount when those that are being grown in test plots or market gardens or for limited specialty markets are included. An economic impact study completed a little over a year ago determined that the potato industry is worth just over a billion dollars annually to the PEI economy directly and in spin-off effects.[1]

Individual potato farms on PEI range in size. The Robinson farm grows around 500 acres of potatoes annually in rotation with soybeans, barley, and forages. For the past five months, I have been following Lori from the time she planted the spuds in the ground back in May to their harvesting in October and ending with the washing and packaging process that is now, at the time of writing, underway at the farm.

Let’s begin by finding out what led Lori in her career choice to become a potato farmer. I think it would be fair to say that Lori grew up with potato farming in her bloodline. Her great, great grandfather began growing potatoes in Augustine Cove, PEI, in the early 1800s and successive generations have continued the tradition. She says her decision “to become a potato farmer was part tradition, part general interest in all things science based, and part desire to work with other members of her family in a family-owned and operated business in PEI”. By the time Lori was in her mid to late teens, she knew what her career path would be – she would study agriculture at university and become a farmer.

Lori holds a Bachelor of Science in Agriculture from the University of Guelph where she majored in Agriculture Business. While Lori will be the first to tell you her university degree did not specifically teach her much about growing potatoes (she learned that by doing), her education did teach her how to think critically, solve problems, and manage human and financial resources. These are all skills useful to today’s commercial farmers. Farming is much more than planting seed in the ground and waiting for the produce to grow.

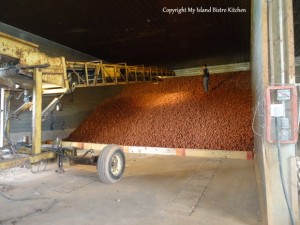

In 2013, Lori grew 15 different varieties of potatoes. This year, 35% of their crop will be used to make potato chips at Frito Lay, 20% will be used for seed, and 45% will be for table stock – the ones that will make it on to our dinner tables. The seed potatoes will be used to plant the farm’s crop next year and also to sell to other potato growers. The potatoes in the large storage bin behind Lori in the photo below are next year’s Norland seed.

Today’s commercial potato farming is very scientific and controlled. Lori points out that “seed potatoes must be inspected in the field by Canadian Food Inspection Agency (CFIA) agents and then tested in an accredited laboratory to ensure that disease levels (viruses) are below a certain percentage before the seed receives certification to be replanted the following year”. It is interesting to note that seed potatoes can be used as table stock but table stock potatoes cannot be used as seed.

The Island spuds will travel. Lori’s farm sells both the seed potatoes and table stock in Canada and the United States while the “chipstock” (those used to make potato chips) will be sold in Canada and the United States as well as in Indonesia, Thailand, and Guatemala. You just never know where you might be eating an Island potato!

All professions have their challenges as well as their sources of satisfaction. Lori says her biggest challenge is finding an adequate number of staff to work on the farm and in their packing house. She currently employs 14 year-round, full time staff and 4-5 seasonal employees from late September to late June. In terms of job satisfaction as a potato farmer, Lori has this to say: “Harvesting a good crop of high-quality potatoes that I eventually see in our local Superstores provides me with a great sense of satisfaction. No two years in potato farming are ever alike. Many new challenges come up every year, every growing season. There is always something new to learn about farming. The need to overcome these challenges to remain successful and the desire to learn new things are what motivate me and make me passionate about my job as a potato farmer.”

Lori has been potato farming for 20 years, continuing on in a long line of successful potato farmers in her family. I asked her what she attributes the success of her potato farm to. She says her predecessors “recognized the importance of good land stewardship in order to achieve the balance between economic viability and environmental sustainability”. Lori has carried on these traditions and philosophy while adding a few of her own ideas along the way to maintain the success of their potato farming operation and carry it into the future.

Lori is very much a hands-on farmer. She actually gets on a tractor and works in the fields herself in the spring doing land preparation work that occurs prior to planting.  On May 29, 2013, when I arrived at a huge long field waiting to be planted in North Carleton, PEI, I found Lori and her crew planting Dakota Pearl potatoes. That’s Lori up on the planter on the right-hand side checking to make sure things are working as intended.

On May 29, 2013, when I arrived at a huge long field waiting to be planted in North Carleton, PEI, I found Lori and her crew planting Dakota Pearl potatoes. That’s Lori up on the planter on the right-hand side checking to make sure things are working as intended.

The farm operates with 7 John Deere tractors, 1 planter, 2 sprayers, 7 tandem trucks, 2 windrowers, 1 harvester, and 3 telescopic pilers.

Farm sizes and farming methods and machinery have changed over the years for sure. I asked Lori what she sees as the biggest changes in potato farming over the years. For her, one change really stands out – input costs for potato farming continually increase while the price farmers receive for the potatoes is relatively unchanged from the days when her grandfather sold potatoes. She also says that a big change has been in the advancement of technology, mainly in the use of GPS for field operations. Lori also notes that, while the Robinson farm has remained relatively the same size since she started farming 20 years ago, most well-established farms on PEI have grown larger at the expense of a number of smaller farms going out of business due to financial strain or lack of a succession plan.

So, let’s look at the timeline of the potato season at the Robinson farm on PEI.

May 29, 2013 – Planting

It all begins with the potato seed for this field of Dakota Pearl variety.

And, well-tilled fertile soil.

And a planter full of potato seed along with some fertilizer.

A good John Deere tractor helps, too!

And, the seed is in the ground!

June 20, 2013 – Fertilizing and Hilling

Field work continues through the growing season to ensure a good crop of potatoes (yes, that’s the Confederation Bridge in the background and, yes, PEI soil really is that red!).

July 2, 2013 – Potato Plants Growing

By early July, there is evidence that the potato plants are growing well – look at that gorgeous emerald green color against the rich red soil of PEI!

July 20, 2013 – Potato Blossoms

A drive by the field in mid-July reveals that the Dakota Pearls are out in blossom!

The field is abloom with white blossoms that have tiny bright yellow centers.

September 30, 2013 – Harvesting

By September 30th, harvesting was underway on the Robinson farm. On this day, I found the crew harvesting the Norland variety (deep red-skinned potatoes) in Albany, not far from the Confederation Bridge.

Two windrowers (one two-row and one four-row) were working the field in advance of the harvester, and moving the freshly-dug potatoes over into the drills where the harvester would pick them up while digging two more rows of potatoes itself at the same time.

This means that the harvester is picking up a total of eight rows of potatoes as it moves down the field.

The harvest days are long and dependent upon good weather and, of course, no mechanical breakdowns.

Once the truck is full of spuds, it heads to the warehouse and an empty truck comes alongside the harvester to be filled as they move in tandem down the long drills of potatoes.

At the warehouse, the spuds are offloaded from the truck on to the conveyer belt that takes them into a small grading house just outside the warehouse where three employees remove any stones, plant particles, or damaged or spoiled potatoes.

From there, via conveyer belt to a bin piler, the potatoes make their way into a huge warehouse that is divided off into separate bins for the different varieties of potatoes.

In the photo below, the man is standing on top of 1/2 million pounds of potatoes in order to insert a temperature probe down into the pile of potatoes to monitor any significant rises in temperature in the middle of the pile which would signal attention needed.

The warehouse is temperature-controlled to maintain the freshness and quality of the potatoes.

By the end of the first day of harvest, 3/4 million pounds of potatoes will have been dug and stored in the warehouse.

Three different sizes of the red potatoes dug on this day will be destined for different uses. The smallest on the lower left of the photo below are mainly sold for restaurant trade where they would be roasted or baked. The next size up are sold in 2 lb or 3 lb bags to grocery stores. Consumers would typically purchase these potatoes to use for roasting or baking at home. The largest of the three sizes are sold in 5 lb poly and 10 lb paper bags to grocery store chains in Canada and the United States for sale mostly as baking potatoes.

In the photo below you can see some of the freshly dug Norlands I brought home with me after my field visit. You’ll find the recipe I used them in at the end of this posting.

Early November, 2013

Before the potatoes make their way to market, they are graded, washed, and packaged on the farm.

Once the potatoes are packaged, they are ready for shipping to markets.

Working with potatoes day in and day out, I was curious as to Lori’s favourite potato dishes. She tells me her favourite way to serve potatoes is to simply toss some small red potatoes with olive oil and herbs and roast them in the oven. She also likes the potato lasagne recipe found on the Prince Edward Island Potatoes Website.

There is nothing like fresh produce straight from the rich red soil of PEI. The day I visited the Robinson farm during harvesting season in early October, I brought some of the Norlands home with me. These beautiful red-skinned variety potato with white flesh are a multi-use potato (they are good boiled, roasted, baked, in salads, and scalloped). I am presenting them here in my favourite old-fashioned scalloped potatoes recipe.

My Island Bistro Kitchen’s Old-fashioned Scalloped Potatoes

1¾ lbs. potatoes (about 3 medium-sized), peeled and sliced about 1/8” thick

1 medium onion, sliced in rings

1½ cups milk

1 tsp liquid chicken bouillon

½ tsp Dijon mustard

2 tbsp flour or cornstarch

Pinch nutmeg

Salt and pepper, to taste

3 tbsp melted butter

½ cup grated cheddar cheese

Paprika

Method:

Preheat oven to 350F.

Assemble ingredients.

Spray or grease a 1½-quart casserole.

Place a layer of sliced potatoes in casserole.

Add a layer of sliced onions.

Repeat potato and onion layers to fill casserole.

In microwaveable bowl, whisk together the milk, chicken bouillon, Dijon mustard, flour or cornstarch, nutmeg, salt, and pepper. Microwave for about a minute, then stir and add the melted butter and 2½ – 3 tbsp. grated cheese. Microwave 1-2 minutes, just until mixture is heated and starts to thicken slightly, stirring once or twice.

Pour warm sauce over the potatoes and onions in the casserole.

Sprinkle with remaining grated cheese and paprika.

Bake, covered, for about 1 hour. Remove cover and continue to bake until potatoes are fork tender, about 20 minutes, or so. Remove from oven and let sit 10-15 minutes before serving. Serves 4-6.

Serve with ham and your favorite side vegetable.

Tips:

Using whole milk or a blend of whole milk and cream will make creamier scalloped potatoes.

Removing the cover during the latter part of the baking process will give the scalloped potatoes a nice crust on top.

Scalloped potatoes have a tendency to boil out of the casserole. To avoid a messy oven clean-up job, place a piece of tin foil on a large baking pan and set the casserole on it. Lightly spraying the tin foil will also make it easier to remove the casserole from the baking pan should the contents bubble out.

My thanks to Lori Robinson for allowing me to follow her potato operation over the past season and for answering my multitude of questions.

Thank you for visiting “the Bistro” today.

Be sure to visit my new Facebook page at My Island Bistro Kitchen. You may also wish to follow me on twitter @PEIBistro and on Pinterest at “Island Bistro Kitchen”.