Be sure to follow me on twitter @PEIBistro as, in the days leading up to Christmas, I will be posting Christmas gift ideas for the foodies on your list.

Monthly Archives: November 2012

Harvest Afternoon Tea

As we draw near to the end of harvest season, and before we embark on the busy Christmas season, I thought I would share some photographs from my Harvest Afternoon Tea. Happy Thanksgiving to our neighbors to the South who are celebrating the American Thanksgiving today (November 22, 2012).

I like the rich colors and tones of autumn – the deep shades of greens, oranges, golds, reds, and rusts.

I love these little matching individual-sized white teapots (photo below)! I don’t have a large collection of china teacups and saucers but do have some seasonal ones like these fall-themed ones.

My harvest tea table has a distinctive fall theme to it, mostly centered around pumpkin!

The cooler autumn days often sees us drawn closer to the warmth of the fireplace.

As much as I love the colors of fall, I love the flavours of the season equally well. One of the least common jams is pumpkin jam and I don’t think I have ever seen it on a store shelf yet it is so tasty and simple to make. I will soon be publishing a separate posting with the recipe for this jam on my blog so don’t throw out those pumpkins just yet as I will have a use to which you can put them!

For my tea table, I chose a fall-themed menu of homemade biscuits served with the pumpkin jam, petite pumpkin muffins perfectly sized for tea-time, shortbread (which you may know by the name “Scotch cookies”), pumpkin tarts, and thumbprint cookies filled with the pumpkin jam.

These are some of my foods of autumn.

I like the tiered stands and use them frequently on tea tables. They are convenient, take up less space on the table, and look impressive.

I was able to find these great peach and yellow-colored tea roses which I think really enhanced the tea table.

My living room mantle dressed for autumn makes a great backdrop for the tea table.

Thank you for visiting “the Bistro” today. There are lots of ways to connect with “the Bistro” through social media:

Join My Island Bistro Kitchen on Facebook

Follow the Bistro’s tweets on twitter @PEIBistro

Find the Bistro on Pinterest at “Island Bistro Kitchen”

Follow along on Instagram at “peibistro”

One Hot Potato – Prince Edward Distillery’s Potato Vodka

PEI has long been known for growing world-class potatoes – they are, after all, our primary cash crop, injecting more than one billion dollars annually into the Island economy, directly and through spin-offs[i]. We all know potatoes as a vegetable on dinner tables and are familiar with them boiled, mashed, baked, as French fries and potato chips, and as the key ingredient in scalloped potatoes. But, would you think of potatoes as a main ingredient in a beverage? Well, there are a couple of industrious and innovative women who have figured out a new use for PEI spuds. Julie Shore and Arla Johnson own and operate Prince Edward Distillery where potato vodka is their flagship product.

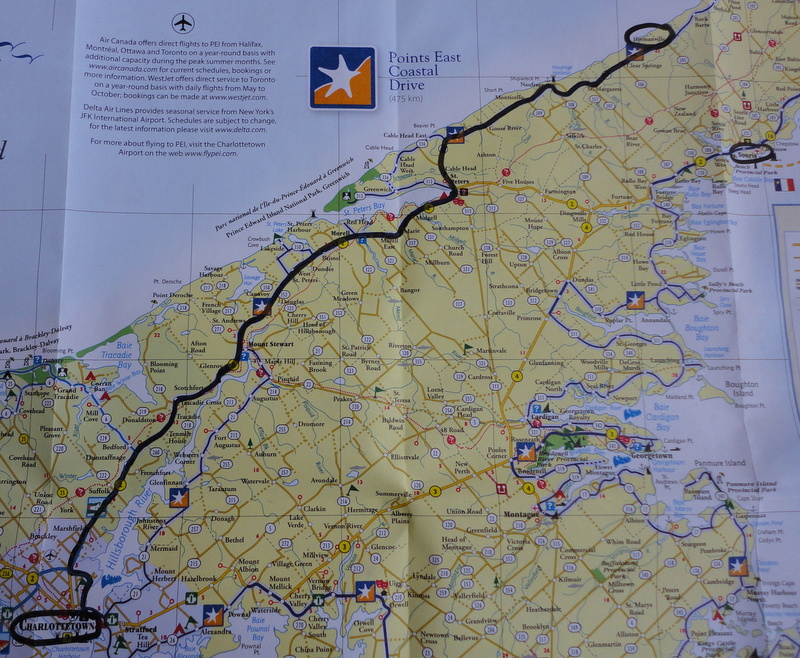

Drive east from the Island’s capital city of Charlottetown along the northeastern shore of the Island and you will find Hermanville, a small rural district not far from the town of Souris in the eastern end of PEI. Late this past summer, I travelled to Hermanville to visit Prince Edward Distillery to find out about this potato vodka. In addition to learning how potato vodka is made, I learned the Distillery is diversifying its operation. They are now producing gin, rye whiskey, rum, and a bourbon-style corn whiskey that sells under the label of IC Shore and that’s in addition to the potato vodka and wild blueberry vodka. Also new this year (2012) are their decadent rum cakes made locally with the Distillery’s Merchantman 1897 rum.

The story of Julie and Arla’s arrival on PEI is similar to several others who have come to the Island and made it their home. They came to PEI on holiday in 1997, fell in love with the Island, and decided to move here. Leaving their jobs behind – Julie as a dental hygiene sales representative and Arla as a psychologist – they built an Inn (Johnson Shore Inn) in Hermanville in 1999, down a long, secluded, and narrow, unpaved lane that leads to a spectacular unobstructed view of the Gulf of St. Lawrence. However, they soon discovered the tourist, and by extension the innkeeper’s, season is short in rural PEI (usually late May to the end of September). That extra time on her hands got Julie thinking about the business her ancestors had been in, pre-prohibition, in North Carolina – distilling apple brandy and bourbon. Living in the land of potatoes, Julie had the idea to set up a distillery to produce potato vodka. Thus, in 2007, Prince Edward Distillery was born with the first batch of potato vodka running from the still’s spigot in 2008.

Julie is the master distiller. In 2011, the Distillery produced 10,000 bottles of the six different liquors the Distillery produces. Apart from her ancestral history of distilling (she’ll tell you distilling is in her blood!), I asked Julie if she had to have special training to be a distiller. She tells me she has taken a distilling course at Cornell University and yeast-making courses in Montreal and France. She and Arla travel the world over visiting distilleries and learning more about the art of fine distilling. Visit their onsite retail outlet and look at the large map on the wall that points out the impressive world travels Julie and Arla have journeyed.

Julie says the best variety of potatoes for potato vodka is Russet Burbank. These spuds are the highest starch potato grown on the Island and the starch content is important for the yeast to work in the fermentation process. The Distillery buys approximately 50,000 pounds of locally-grown potatoes, on an annual basis, to use as the base for potato vodka. Julie explains that it takes about 18 pounds of potatoes to produce one 750 ml bottle of the potato vodka so, as you can imagine, it takes a lot of spuds to yield any amount of vodka. While potato vodka is not unheard of, it is more rare since 99% of vodkas on the market are grain-based. That’s probably because, as Julie says, potato vodka is difficult to distill due to the fact that potatoes are approximately 80% water, have to be cooked, and it takes such a volume of the raw ingredient (potatoes) to produce the final product.

Making potato vodka is very labour intensive. The potatoes are ground and cooked to break down their starch into fermentable sugars so that fermentation will occur with the addition of yeast (wait till you hear what is done with the leftover mash from the potatoes and who the benefactors are!). The mixture is fermented for four days in 1000-gallon tanks to form alcohol.

Using a 680-litre German-made Holstein copper vertical still that Julie had imported from Germany and capably assembled herself (since it came in parts and didn’t come with an instruction book), this fermentation mixture is distilled three times to remove impurities, achieve a neutrality of the alcohol, and to get the perfect alcohol content for the vodka. Julie tells me it takes 10-14 days to produce a batch of vodka from start to finish, raw product (potatoes) to bottling.

The Distillery has enjoyed sweet success and very early in its operation. Their products rank among the best. Just a year after producing their first vodka for market, the potato vodka won gold in the 2009 San Francisco World Spirits Competition and, in the same year, the wild blueberry vodka won silver in the UK International Spirits Challenge in London, England. Yes, our locally-produced Island wines and spirits can match any on the market!

Prince Edward Distillery supports local producers, buying and using locally-produced potatoes, grains, and blueberries in their liquor production. The Distillery employs between 4-6 full time employees and 1 part-time employee on a seasonal basis. Currently, their products are sold in PEI and Nova Scotia markets. However, they are exploring markets farther afield.

This past summer, the Distillery decided to open a spirits outlet shop at Peakes Quay on the Charlottetown waterfront, a popular tourist attraction of small shops and not far from the seaport where dozens of cruise ships dock each year. In addition to the Peakes Quay location (open seasonally), the Distillery’s products are available at the onsite retail shop in Hermanville and in PEI and Nova Scotia liquor stores.

So, about that mash I mentioned earlier – the left-over potato product after the liquid has been extracted for the vodka. Well, behind the distillery may well be what many have dubbed as the most cheerful hogs on the Island! Yes, that’s right, hogs or, more specifically, Heritage Berkshire pigs which Julie raises on the mash. She says there are lots of nutrients left in the potato mash so why throw it out when she can raise pigs on it!

The Distillery is open daily, May – October, for tours and taste-testing; from October – May, it is open by appointment or by chance. A tour of the Distillery and taste-testing of two spirits costs $10. (or, if you simply want to taste any spirit, it is $3./taste). For more information on the Prince Edward Distillery, visit their website, call them at 902-687-2586, or, better still (pun intended!), take the scenic northeastern shoreline route to Hermanville and visit the Distillery at 9985, Route 16.

True to tradition, when I visit a local producer, I bring home their product and create a recipe with it. I decided to create a Vodka Tomato Sauce for pasta using Prince Edward Distillery’s potato vodka. I find the vodka actually goes well with tomatoes and draws out the tomato flavour and makes it pop without adding a competing flavour to the dish. The key, of course, is not to over-do it – less is often more and the idea is that the vodka enhance and contribute to the taste of the sauce, not overpower it. My recipe creation follows.

Thank you for visiting “the Bistro” today. There are lots of ways to connect with “the Bistro” through social media:

Join My Island Bistro Kitchen on Facebook

Follow the Bistro’s tweets on twitter @PEIBistro

Find the Bistro on Pinterest at “Island Bistro Kitchen”

Follow along on Instagram at “peibistro”

Tomato Vodka Pasta Sauce

By Published: November 15, 2012

- Yield:

- Prep: 10 mins

- Cook: 50 mins

- Ready In: 60 mins

A rich, flavourful tomato sauce suitable for various types of pasta

Ingredients

- 1 tbsp olive oil

- 1 tbsp butter

- 2/3 cup onion, chopped

- 1/2 cup celery, chopped

- 1/2 cup green pepper, chopped

- 1 cup mushrooms, chopped

- 3 cloves garlic, minced

- 1 540ml can diced tomatoes, undrained

- 2 1/2 tbsp corn starch

- 1/2 cup chicken stock, cooled

- 1/2 cup tomato sauce

- 2/3 cup Prince Edward Distillery Potato Vodka

- 1/2 cup whipping cream

- 1/2 tsp dried oregano (or 2-3 tsp fresh)

- 1 tbsp dried basil (or 2 - 2 1/2 tbsp fresh)

- 2 tsp fresh chives, chopped

- 1/8 tsp cayenne pepper

- 1/8 tsp red pepper flakes

- 1 tbsp fresh parsley, chopped

- 1/2 cup freshly grated Parmesan cheese

- sea salt, to taste

- pepper, to taste

Instructions

Heat oil and butter in large pot. Add onion, celery, green pepper, mushrooms, and garlic. Sauté 2-3 minutes over medium heat.

Heat oil and butter in large pot. Add onion, celery, green pepper, mushrooms, and garlic. Sauté 2-3 minutes over medium heat. Add diced tomatoes, salt, and pepper. Simmer over low heat 5-7 minutes.

Add diced tomatoes, salt, and pepper. Simmer over low heat 5-7 minutes. Whisk the corn starch with the cooled chicken stock until smooth.

Whisk the corn starch with the cooled chicken stock until smooth. Stir tomato sauce, vodka, and chicken stock/cornstarch into mixture. Simmer 18-20 minutes, until slightly thickened.

Stir tomato sauce, vodka, and chicken stock/cornstarch into mixture. Simmer 18-20 minutes, until slightly thickened. Stir in whipping cream, oregano, basil, chives, cayenne, red pepper flakes, and parsley. Simmer 7-10 minutes.

Stir in whipping cream, oregano, basil, chives, cayenne, red pepper flakes, and parsley. Simmer 7-10 minutes.- Meanwhile, cook pasta according to package directions and drain. Add drained pasta to tomato sauce and toss to coat.

- Spoon pasta into serving dishes. Garnish with freshly grated Parmesan cheese, fresh basil, a spring of parsley, and halved cherry tomatoes.

WordPress Recipe Plugin by ReciPress

War Cake – A Part of Wartime Culinary History

![Remembrance Day Service at the Cenotaph in front of Province House, Charlottetown, PEI, Canada [11 November 2012]](https://myislandbistrokitchen.com/wp-content/uploads/2012/11/1-DSC07462.jpg)

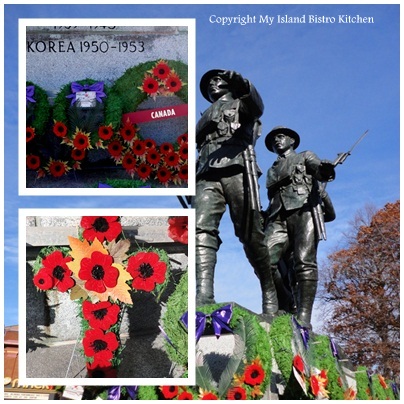

Those of us who have been fortunate enough never to have known or experienced war have opportunities to demonstrate our respect and gratitude for, and remembrance of, these acts of bravery and sacrifice. For example, we wear a poppy on the left breast, close to the heart to signify remembrance of the lives lost.

Thousands of people across the country will attend Remembrance Day ceremonies in their local communities where they will respectfully observe a moment’s silence at 11am on the 11th day of the 11th month to mark the time the Armistice was signed to end WWI. Wreaths will be laid in commemoration.

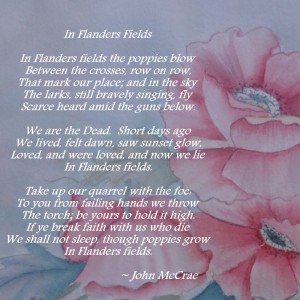

One of the most well-known poems about war was written in May, 1915, by Lt. Col. John McCrae, a Canadian Medical Officer in WWI. While stationed near Ypres, Belgium, where some of the most horrific and bloodiest fighting of WWI occurred, he was motivated to write about the death he saw around him and of the prolific red poppies growing amidst the devastation of war in the Flanders area of western Belgium. His poem, “In Flanders Fields” has become synonymous with Remembrance Day in Canada and Lt. Col. McCrae is often credited with being the catalyst that led to the poppy being identified as the symbol of remembrance of the blood shed by soldiers who were casualties of battle.

On this Remembrance Day, I am going to focus my food blog feature story on war cake, a wartime dessert that is still made and served in several Island households today.

As a small child I well remember my grandmother making war cake and this was long after WWII had ended. I loved her war cake! It is such a simple raisin-spice cake that is characterized by the absence of eggs and milk — ingredients that would have been scarce during wartime. This cake is sometimes referred to as “boiled raisin cake” because raisins form the main content and the majority of the ingredients are boiled, then cooled, before they are mixed with flour and baking soda and then baked in the oven. Because of food shortages during war time, many foods were rationed.

Born of necessity, homemakers during wartime became resourceful, frugal, adaptable, and creative in order to feed their families. Cooking tended to be very basic. Women were known to have saved their ration stickers so they could buy the raisins and sugar that the war cake recipe called for – thus war cake would have been a very prized commodity.

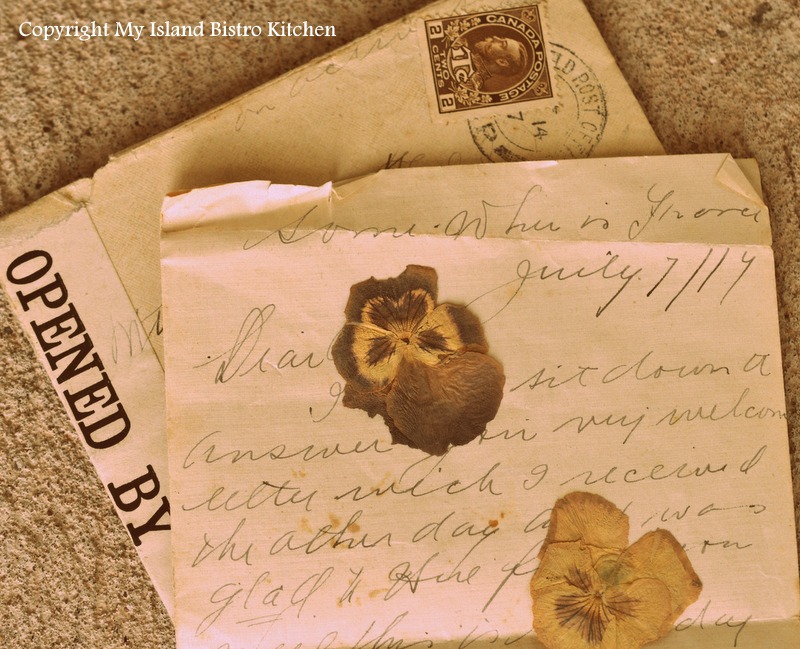

War cake was made for consumption on the home front but many also made the cakes in tin cans and packed them in socks, mittens, and underwear they were shipping overseas for their loved ones serving in the war. Imagine the excitement when a soldier would have received this package from home and discovered a mother’s or sister’s war cake inside! Amazingly, with the slow mail and ship service during WWI and WWII, there is evidence these cakes were received as the soldiers would refer to them in their letters home, letters that would have looked much like the July 7, 1914, letter in the photograph below.

In my research for this story, I examined many recipes for war cake and found similarities amongst them all. Some were very sketchy in terms of amount of ingredients to be put in the batter and many were almost totally devoid of any directions. While the amounts of the ingredients may vary slightly, all of the recipes I reviewed were essentially the same in ingredient content. All called for big, sticky raisins (you may know these as “Lexia” raisins), a variety of spices of the cook’s choice, either brown or white sugar or a combination of both, shortening or lard, boiling water, flour, and soda. One thing I noted was the significant amount of sugar that the recipes called for – i.e., two cups per cake. Sugar was one item that was commonly rationed during wartime and a cake taking two cups of sugar would certainly have been considered a luxurious dessert, I am sure. Flavour may vary from cake to cake based on spices used in the batter. The choice of spices varies but typically consisted of cinnamon, nutmeg, and cloves, as a minimum, with ginger frequently appearing in recipes. I added mace and cardamom to my cake to give it a bit more flavour (recipe follows at end).

I am told these cakes were often made with lard (as opposed to butter) for a couple of reasons. First, lard has a longer shelf life than butter would have had and, for cakes being sent overseas to the soldiers, it would have been a long journey for the cakes to reach Europe so shelf life of the cakes was an important factor. Second, butter was often scarce during wartime because there were no big herds of cattle on local farms so butter would have been used sparingly, even for those living on farms and churning their own. Lard, on the other hand, would have been much more readily available, particularly on farms. I found a couple of recipes that indicated either butter or shortening could be used in the recipe; however, butter was called for in a much lesser quantity than the shortening, if the latter was used instead. For example, I found one recipe that called for 2 tablespoons of butter or 1 cup of shortening which demonstrates how judiciously butter would have been used, if at all.

While its ingredients are simple, war cake takes some time to make. All of the ingredients, except the flour and soda, are boiled on the stove for 5 minutes. Then it is important to let the boiled raisin mixture cool to room temperature as the mixture will thicken naturally on its own as it cools. This will normally take 4-5 hours. If the flour and soda are added into a mixture that is too hot, the result is likely to be a gummy cake. When the raisin mixture is cooled, the flour and soda are stirred in and the mixture turned into the baking pan. My grandmother made her war cake in a loaf pan; however, traditionally, war cake seems to have been made in some kind of a round pan – usually a tube pan or, in the case of overseas shipping during war time, in tin cans. War cake is a very dense cake which makes it sometimes difficult to get the center of the cake baked without drying out the outside edges. It is also a heavier type cake which makes it somewhat prone to falling in the center. A tube (or Bundt pan, if you have one) removes the baking uncertainty and helps the cake to bake more evenly.

War cakes take, on average, about an hour to bake. The old recipes I reviewed didn’t even mention baking the cake let alone at what temperature (in fact, one recipe simply said “to thicken” but didn’t elaborate on what thickening agent was to be used!). These recipes predate our modern electronic ovens! While some suggest baking the cake at 350F, I thought that might be a bit high so I baked my war cake at 335F for one hour. Because there are no eggs or milk in the cake for moistness, it is very easy to overbake the cake and end up with a dry product. Hence, it is important to time the baking carefully and to use a cake tester starting at about the 45-minute point. If the cake starts to darken on the top or edges too quickly, simply place a piece of tin foil loosely over the top. Adding a small pan of water to the lower shelf in the oven while baking the cake will also help to keep the cake moist.

Because of the texture of the cake, it may seem soft on the top and not baked; however, if a cake tester comes out of the cake clean, it’s time to remove it from the oven before it dries out.

War cake is a “stick to the ribs” substantial, hearty kind of cake. It goes particularly well with a nice cup of tea.

In keeping with the traditional way war cake was served, I have photographed the cake plain, just as it would have been eaten during wartime.

War cake was not traditionally iced. However, it would be lovely served with a dollop of whipped cream or vanilla or maple ice cream. It could also be dressed with a brown sugar sauce or, to make a plain cake really decadent, why not serve all three – ice cream, brown sugar sauce, and whipped cream!

Regardless where you are in the world, if you have any wartime memories (either your own or those passed down to you from your ancestors) of war cake made for consumption on the home front or to send to the soldiers fighting the war, I would love to hear about them. War cake is a part of wartime culinary history.

Here are some photographs of the Remembrance Day Ceremony at the cenotaph in downtown Charlottetown, PEI, this morning.

![Remembrance Day in Charlottetown, PEI [11 November 2012]](https://myislandbistrokitchen.com/wp-content/uploads/2012/11/1-Parade.jpg)

![Hon. Robert W.J. Ghiz, Premier of the Province of Prince Edward Island lays a wreath on behalf of the people of the Island at the Remembrance Day Service in Charlottetown, PEI [11 November 2012]](https://myislandbistrokitchen.com/wp-content/uploads/2012/11/1-Premier-Ghiz.jpg)

![Small Child Watches as a Veteran lays a Wreath at the Remembrance Day Service in Charlottetown, PEI ]11 November 2012]](https://myislandbistrokitchen.com/wp-content/uploads/2012/11/1-Joyce-Paynter-and-Child.jpg)

![Veterans Laying Wreaths at Remembrance Day Service in Charlottetown, PEI [11 November 2012]](https://myislandbistrokitchen.com/wp-content/uploads/2012/11/1-Veterans-Laying-Wreaths.jpg)

![Canada Flag Flies at Half-Mast on Remembrance Day, Charlottetown, PEI [11 November 2012]](https://myislandbistrokitchen.com/wp-content/uploads/2012/11/1-Flag-and-wreaths.jpg)

War Cake

Ingredients

- 3/4 cup shortening

- 2 cups brown sugar, lightly packed

- 1 pound large, sticky raisins

- 1 tsp salt

- 1 tsp cinnamon

- 1 tsp nutmeg

- 1/2 tsp cloves

- 1/4 tsp ginger

- 1/8 tsp mace

- 1/8 tsp cardamon

- 2 cups boiling water

- 3 cups all-purpose flour

- 2 tsp soda

Instructions

- Assemble ingredients.

- Place the shortening, brown sugar, raisins, salt, spices, and boiling water into a large saucepan. Over medium-high heat, bring mixture to a boil. Reduce heat to medium or slightly lower and boil mixture for five minutes. Remove from heat and set saucepan on cooling rack. Let mixture cool to room temperature (4-5 hours), stirring occasionally.

- In bowl, whisk the flour and baking soda together. Set aside.

- Grease large tube or Bundt pan.

- When raisin mixture has cooled completely, add the flour and baking soda. Stir until dry ingredients have been completely mixed into the raisin mixture.

- Spoon mixture into greased pan. Add a small pan of hot water to lower shelf in oven for moisture while cake is baking. Bake cake on middle rack in 335°F preheated oven. If cake starts to brown on the top too quickly, loosely place a piece of tin foil on top of cake. Bake apx. 1 hour but begin to test cake for doneness, using a cake tester, at the 45-minute point as cake can dry out very quickly.

- Remove cake from oven and place pan on cooling rack for 10 minutes then remove from pan. Allow cake to cool completely before cutting.

Recipe Notes

[Copyright My Island Bistro Kitchen]

Connect with My Island Bistro Kitchen on Social Media

Join the Facebook page for My Island Bistro Kitchen: https://www.facebook.com/MyIslandBistroKitchen/

Follow “the Bistro” on “X” (formerly Twitter): https://twitter.com/PEIBistro/

See the drool-worthy gallery of mouth-watering food photos from My Island Bistro Kitchen on Instagram: https://www.instagram.com/peibistro/

Follow “the Bistro” on Pinterest at https://www.pinterest.ca/peibistro/ and pin the Pinterest-ready photo at the end of this posting to your favorite Pinterest boards!

Follow the PEI Potato Farmer! From Field to Table

One crop we grow really well on this Island is potatoes. Our PEI spuds are world-class quality and often win awards on the national stage. According to statistics obtained through the Prince Edward Island Potato Board, 86,500 acres of potatoes were grown on the Island in 2012. An economic impact study was completed in 2012 showing that the potato industry contributes over one billion dollars annually to the PEI economy, either directly or through spin-off effects. Now, that’s no small potatoes!!!

Last spring, I was looking for a potato operation and a potato field that I could follow from planting through to harvesting specifically for this blog post entry. It’s one thing to go into the supermarket and purchase a bag of potatoes but it is quite another to know where the potatoes come from and to watch them grow and I thought my readers would be interested to see some photographs of potato growing and harvesting on PEI. One evening in mid-May, I was heading from Summerside to Charlottetown “through the 225” as the locals refer to one of the shortcut routes between the two cities, when I came across this rather large and odd-looking black machine pulling into a huge field.

![Filler Machine Loads Seed Potatoes Into Potato Planter in Warren Grove, PEI [19 May 2012]](https://myislandbistrokitchen.com/wp-content/uploads/2012/11/1-Filler-Machine.jpg)

![Preparing to Plant Russet Burbank Potatoes in Warren Grove, PEI [19 May 2012]](https://myislandbistrokitchen.com/wp-content/uploads/2012/11/1-Harrowing-Fertilizing-and-Planting.jpg)

Robert, the man driving the big John Deere tractor that was hauling the rather ominous looking black machine, was very willing to explain what the machine was. I learned it is called the “filler machine” – it brings the cut potato seed from the warehouse to the field where it is then loaded into the planter. I asked if it would be okay if I took some photographs of the machine as it filled the planter. Robert explained that I’d have to be quick if I wanted to get a picture of it as it speedily fills the planter that backs in under it. Quick isn’t the word for it – it’s more like ‘in a blink of an eye’ and then the planter pulls away from the filler machine and off it goes down the field to plant the spuds.

![Planting Potatoes in Warren Grove, PEI [19 May 2012]](https://myislandbistrokitchen.com/wp-content/uploads/2012/11/1-Planting.jpg)

The Potato Board says, over the past three years, PEI seed and table potatoes have been shipped to over 30 countries besides Canada and the United States. No matter where you are, chances are you may have sampled PEI potatoes! The next time you are in your local supermarket, be sure to check the bags of potatoes to see if they may have come from the rich and fertile red soil of PEI, Canada.

On June 25th, I found the field was lined with neat rows of bright green leafy plants. The potatoes were growing well!

Over the next several weeks I would periodically drive by the field to see if the delicate white potato blossoms would appear. Sure enough, on August 8th, I found they were out in blossom.

![Potatoes Blossoms [8 August 2012]](https://myislandbistrokitchen.com/wp-content/uploads/2012/11/1-Potato-Blossoms-Superimposed.jpg)

![Russet Burbanks in Blossom [8 August 2012]](https://myislandbistrokitchen.com/wp-content/uploads/2012/11/1-Potato-Blossoms.jpg)

![Harvesting the Russet Burbank Potatoes in Warren Grove, PEI [7 October 2012]](https://myislandbistrokitchen.com/wp-content/uploads/2012/11/1-Potatoes-Close-up-with-Colored-Leaves.jpg)

How many workplaces have a gorgeous backdrop of fall foliage like this one does! And, I was lucky enough to spend part of an afternoon in this workplace, following the harvesting equipment. There is nothing like the smell of fresh PEI soil turning up spuds on a crisp, sunny October afternoon!

![Potato Harvesting in Warren Grove [17 October 2012]](https://myislandbistrokitchen.com/wp-content/uploads/2012/11/1-DSC_0961.jpg)

![Potato Harvesting in Full Swing in PEI [17 October 2012]](https://myislandbistrokitchen.com/wp-content/uploads/2012/11/1-Potatoes-Close-up.jpg)

![Potato Harvesting in PEI [17 October 2012]](https://myislandbistrokitchen.com/wp-content/uploads/2012/11/1-DSC_0972.jpg)

![Windrowing and Digging in the Evening [17 October 2012]](https://myislandbistrokitchen.com/wp-content/uploads/2012/11/1-Windrowing-and-Digging-at-Night.jpg)

![Potato Harvesting at Night [17 October 2012]](https://myislandbistrokitchen.com/wp-content/uploads/2012/11/1-1-DSC_0951.jpg)

My thanks to Smith Farms of Newton, PEI, for allowing me to follow their potato planting and harvest cycle this year.

Thank you for visiting “the Bistro” today. There are lots of ways to connect with “the Bistro” through social media:

Join My Island Bistro Kitchen on Facebook

Follow the Bistro’s tweets on twitter @PEIBistro

Find the Bistro on Pinterest at “Island Bistro Kitchen”

Follow along on Instagram at “peibistro”